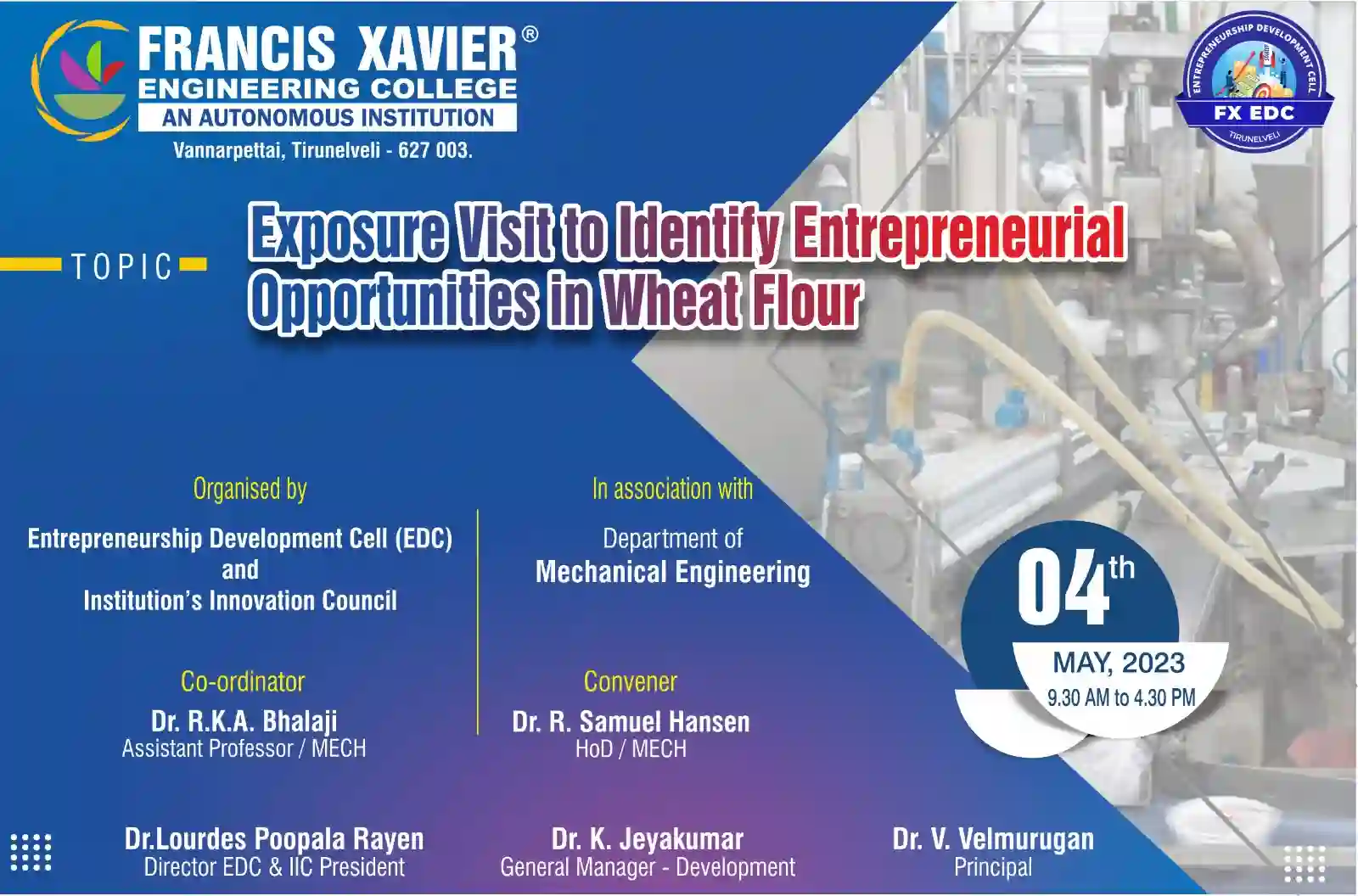

On 04th May, 2023 an “Exposure visit to Wheat Flour Mill to identify the Entrepreneurial Opportunities” was organized by Entrepreneurship Development Cell & Institution’s Innovation Council in association with the Department of Mechanical Engineering from 09:00 am to 04.00 pm. A batch of 55 Third year students from the Department of Mechanical Engineering and 2 staff members participated in the exposure visit.

Students visited the “Naga Flour Mills, Dindigul to expose the manufacture of Wheat Flour Mill and the entrepreneurial opportunities available in the sector. The concern presented a video about history of Naga Flour Mill and manufacturing process. They said that Naga Flour manufacture 28 food products. The products are distributed for the domestic consumption and exported to various foreign countries also. They procure different raw materials as per product requirements from Unit I of Naga Mills, Dindigul. Initially R&D team testing the raw materials as per nutrition requirements of each and every product. Continuously sewing process is done using copper machine for the purpose of raw material filtration. After that raw materials are supplied into extruder with the combination of both water & powder through hopper. Subsequently, raw materials are shaken around 25mins, next stage is to dry the materials around 70 – 80 Degree Celsius. For reducing the temperature for packing, store and cool the materials with 30 Degree Celsius. In addition to this, before packing metal detector is used to find the any metal in production process. Finally food products are packed for sale using automation process.